SPECIFICATIONS

Accuracy: Approx. 0.01mm

Brand Name: BULK-MAN 3D

CNC or Not: CNC

Certification: CE

Color of Aluminum Profiles: Silver or Black Anodized

Condition: New

Controller: Offline,DDCS Offline Control or Mach3 Control for Choice

Frame Material: 6063-T5 High-Strengh Aluminum

Frame Size: 1000x1000mm or 1500x1500mm

High-concerned chemical: None

Max Working Area(X*Y*Z): 1300x1300x150mm

Model: OX MAN CNC Router Complete Kit

Model Number: OXMAN CNC FULL KIT

Motor for Each Axis: 2.2N.m Close Loop Stepper Motor

Origin: Mainland China

Thickness of CNC Plates: 12mm

X Axis and Y Axis Ball Screw: SFU1610 (Diameter 16mm)

Z Axis Ball Screw: SFU1204(Diameter 14mm)

Z-Axis Maxinum operating speed: F10000~F20000mm/min

Industrial Grade OX-MAN CNC Complete Kit - 1610 Ball Screw Trammission |

The OXMAN CNC Router – a revolutionary industrial-grade CNC machine engineered for unparalleled performance and precision. Featuring state-of-the-art SFU1610 (16mm) ball screws, Double HG&MGN Linear Rails & Extended Linear Blocks, this upgraded model builds on the success of the top-selling Ultimate Bee CNC Machine. It is 100% fully self-developed, designed by BulkMan3D International R&D Team and copyrighted by BulkMan3D.

Machine Specification:

01. Configuration: 4-Axis Trammission CNC Engraver

02. Frame Material: High Strength●Corrosion 6063-T5 Aluminum

03. Available Models (Frame Size): 1000x1000mm | 1500x1500mm

04. Working Stroke (X*Y*Z):

1000x1000mm: X-Axis=800mm(31.50in), Y-Axis=800mm(31.50in), Z-Axis=150mm(5.91in)

1500x1500mm: X-Axis=1300mm(51.18in), Y-Axis=1300mm(51.18in), Z-Axis=150mm(5.91in)

05. Overall Dimensions (Including Motors):

1000x1000mm: X-Axis=1165mm(45.87in), Y-Axis=1130mm(44.49in), Z-Axis=710mm(27.95in)

1500x1500mm: X-Axis=1665mm(65.55in), Y-Axis=1630mm(64.17in), Z-Axis=710mm(27.95in)

06. Transmission on X/Y/A-Axis: SFU1610 Precise Ball Screw + HG15 Extended &Dual Linear Rails

07. Transmission on Z-Axis: SFU1204 Precise Ball Screw + MGN15 Extended &Dual Linear Rails

08. Recommend Supported Weight of Z-Axis(Spindle Motor): 6.5kg

09. Motor Type (X/Y/Z/A-Axis): Precision 2.2N.m Close Loop Stepper Motor

10. Thickness of CNC Aluminum Plates: 12mm

11. Maxinum Operating Speed: F10000mm/min ~ F20000mm/min

12. Cutting Speed(G1): F10~F4000/6000mm/min

13. Gross Weight of Shipment: Approx. 90kg~136kg

14. Warranty: 1.5 Years Online Supports

This Complete CNC Router Includes: |

|

|

● Optional Sizes OXMAN CNC Series ○1000x1000 (Working Area:800x800x150mm | 31.50x31.50x5.91in) ○1500x1500 (Working Area:1300x1300x150mm | 51.18x51.18x5.91in) ● Options As Picture Shows Different Workbench ○OXMAN (with simple workbench) ○OXMAN PRO (with upgraded workbench-1640 profiles) ○OXMAN ULTRA (with deluxe workbench-15160 profiles + rear baffles) ● Options As Picture Shows Spindle Motor Kit with Dust Cover ○2.2KW 110/220V Air-Cooled (High-Speed 7-Series 4-Bearings) ○2.2KW 110/220V Water-Cooled (High-Speed 7-Series 4-Bearings) ● Options As Picture Shows Controller Box ○DDCSV4.1 Intergrated Controller Box System - Offline Control ○UC300 Intergrated Controller Box System - Mach3 Control ● 4 Pcs 2.2N.m Closed Loop Stepper Motors

● Complete Wiring Shielded Cable Kit with Connectors ● New Design Extended Interior-Opening Type Cable Chain System ● After Assembly, You will Get the Complete Machine as shown in Picture! ● Free Gifts: XYZ Touch Probe + 10 pieces High-Speed End Mills ProTips: The VFD and all the Internal cables and modules inside this control box have been pre-connected, just simply connecting the aviation plugs according to our instruction manual then it is ready to work for you.

|

Key Features |

✅ [Robust Aluminum Frame] Constructed with a robust 6063-T5 aluminum alloy frame, the OXMAN CNC ensures exceptional durability and stability, effectively reducing vibrations for smooth, precise operation over extended machining sessions.

✅ [Precision Locating Pins] Each key component uses precision pins for perfect alignment, while robust metal covers and reinforced aluminum protect all axes for superior stability. Even DIY CNC users can achieve accurate setup without professional tools.

✅ [2.2KW Spindle Motor] Powered by a potent 2.2KW spindle motor, the OXMAN CNC offers impressive torque and speed across various materials, ensuring superior cutting and engraving performance even on the toughest substrates.

✅ [High-Precision Stepper Motors] Outfitted with advanced 2.2N.M closed-loop stepper motors, the OXMAN delivers consistent and repeatable results, enabling high-quality cuts and engravings with minimal deviation.

✅ [Enhanced Precision with Ball Screws] Equipped with premium ball screws, the OXMAN improves movement accuracy and efficiency, reducing backlash and guaranteeing smoother, more precise cuts.

✅ [Dual Linear Rails & Extended Blocks] Featuring dual linear rails & extended blocks, the OXMAN enhances stability and ensures smoother motion, delivering accurate and reliable machining results even under heavy loads.

✅ [Durable 304Stainless Steel Screws] Incorporating stainless steel screws throughout its build, this machine resists wear and corrosion, extending its lifespan while consistently maintaining high precision.

✅ [Versatile Workbench Options] Offering three distinct workbench configurations, the OXMAN accommodates various budgets and applications—ideal for both heavy-duty tasks and everyday use.

✅ [New Design Interior-Opening Cable Drag Chain] The enhanced cable drag chain optimizes cable management, shielding them from wear and reducing friction, which in turn supports smoother machine movements and improved reliability.

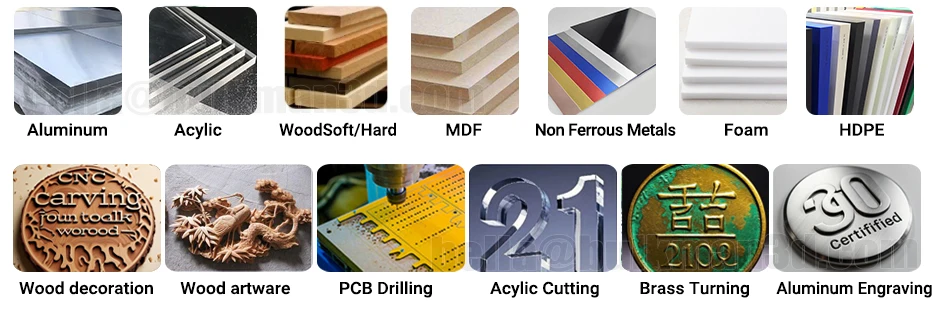

✅ [Compatible Materials for Cutting/Milling/Engraving]

Perfect for aluminum, hardwood, plywood, PVC, plexiglass, Delrin, PCB boards, light metals, and more.

✅ [UC300 Mach3 4-Axis Controller Cabinet (Pre-Connected)]

Equipped with the cutting-edge UC300 Mach3 Controller—a USB-based motion controller designed for CNC systems—the OXMAN seamlessly integrates with Mach3 software to deliver precise, dependable control over all operations.

✅ [DDCSV4.1 Offline 4-Axis Controller Cabinet (Pre-Connected)]

Its rugged, plug-and-play design offers full Fanuc G-code integration and versatile CAD/CAM support for engraving, milling, and more. Pre-connected and modular, it simplifies setup while delivering reliable CNC performance.

Frequently Ask Questions |

Q1:What are the differences among the OXMAN, OXMAN PRO and OXMAN ULTRA? |

Q2: Is this a complete cnc router comes with everything ready to work? |

Q3: What about the Accuracy of the OXMAN CNC Series? |

Q4: How to assemble this CNC? |

Q5: How to Choose the Controller? |

Q6: How to Choose the Spindle? |

Q7: What about Warranty and Technical Support? |

OXMAN CNC Engraver: 1 Machine, 100+ Materials Mastery |

OXMAN CNC Engraver: 1 Machine, 100+ Materials Mastery

✔️ Cut/Engrave/Mill Anything

From aluminum, brass to wood, plexiglass & foam – even your toughest creative challenges.

✔️ Smart & Compact

20,000mm/min hyper-speed + auto safety sensors fit on any desk.

🔧 Compatible Materials

Metals | 12+ Woods | Plastics | Leather/Foam

✔️ Perfect For

Custom Gifts | Metal Tool Engraving | Wooden Signage | Industrial Prototyping

Features of Magic-Cube DDCS4 V4.1 4-Axis Offline Controller Box System |

|

The BulkMan3D Magic CubeDDCS4 V4.1 Offline Control Box is an Integrated &Industrial-grade Controller with high-performance control system specially designed to meet the needs of industrial manufacturing. Its rugged exterior and state-of-the-art technology ensure precise control of all CNC machine functions. The DDCS V4.1 is a standalone/offline controller, supports comprehensive between the computer and DDCS V4.1 controller, no size limited of the G-code file. The G-code design supports various software of CAD/CAM, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on. Meet the needs of various CNC machines: Engraving machines, Milling machines, Routers, Cutting...etc. Hardware Configuration inside this Control Box: ● 1x DDCSV4.1 Controller ● 1x MC MPG HandWheel ● 1x MC Power Supply S-800W-36V ● 1x MC Power Supply LRS-75W-24V ● 1x MC VFD 2.2KW- 220V or 110V ● 4x HBS57S Stepper Driver ● 1x MC Plug-in Filter CW4L2-20A ● 1x MC Wire-lead Filter CW1B-10A ● 1x MC 4-channel relay-24V ● 1x MC Cooling Fan 8025-24V ● 2x MC Cooling Fan 6010-24V ● 1x MC DB37 Terminal Block DDCSV4.1 Key Features: ● Supports both of offline and computer CNC systems. ● Supports for split or integrated hybrid servo motors. ● Adopts a modular design for easy installation and maintenance. ProTips: The VFD and all the Internal cables and modules inside this control box have been pre-connected, just simply connecting the aviation plugs according to our instruction manual then it is ready to work for you. |

|

| ||||||

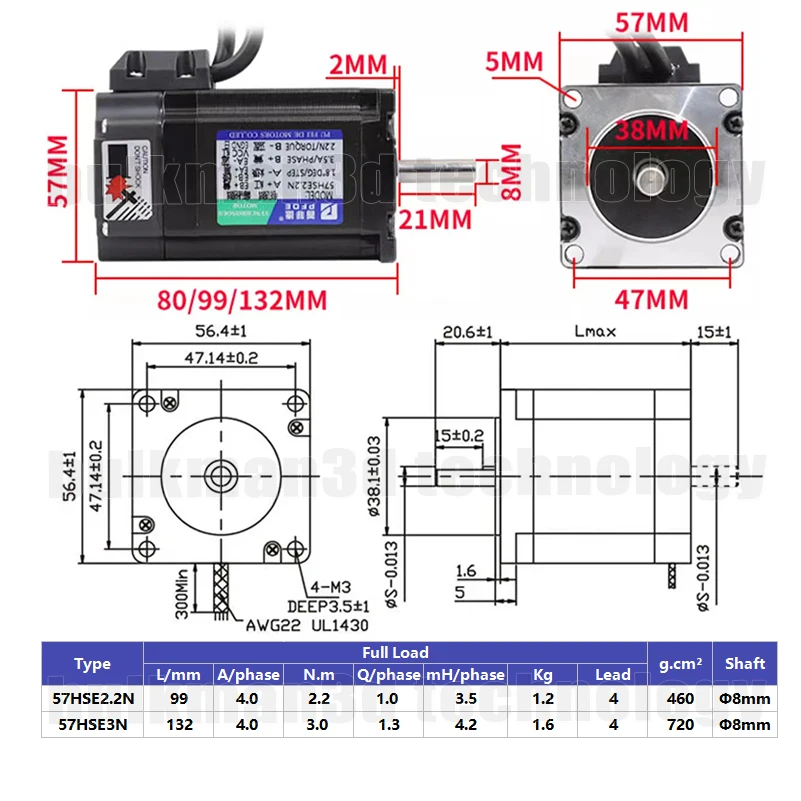

Features of 2.2N.M Close-Loop Stepper Motors |

|

● Stepper Motor model: 57HSE2.2N

● Shaft Diamater: 8mm

● Motor Current: 3.5A

● Hold Torque:2.2N.M

● Encoder cable: 5000mm

● Motor cable: 5000mm

● Rated voltage/current: 3.5A

● Outlet mode: single output shaft

● Rated speed: 1000 rpm (no-load speed: 2000 rpm)

● Outlet mode: two-phase four-wire (must be wired according to motor label

Key Features:

- High Precision: Achieves accurate positioning, good for fine control like micro-machining.

- Strong Torque Output: 2.2N.m torque can handle heavier loads, ensuring

reliable operation.

- Closed-Loop Control: Continuously monitors and corrects position errors for

stable running.

- Energy-Efficient: Adjusts current based on load,reducing energy consumption.

|

|

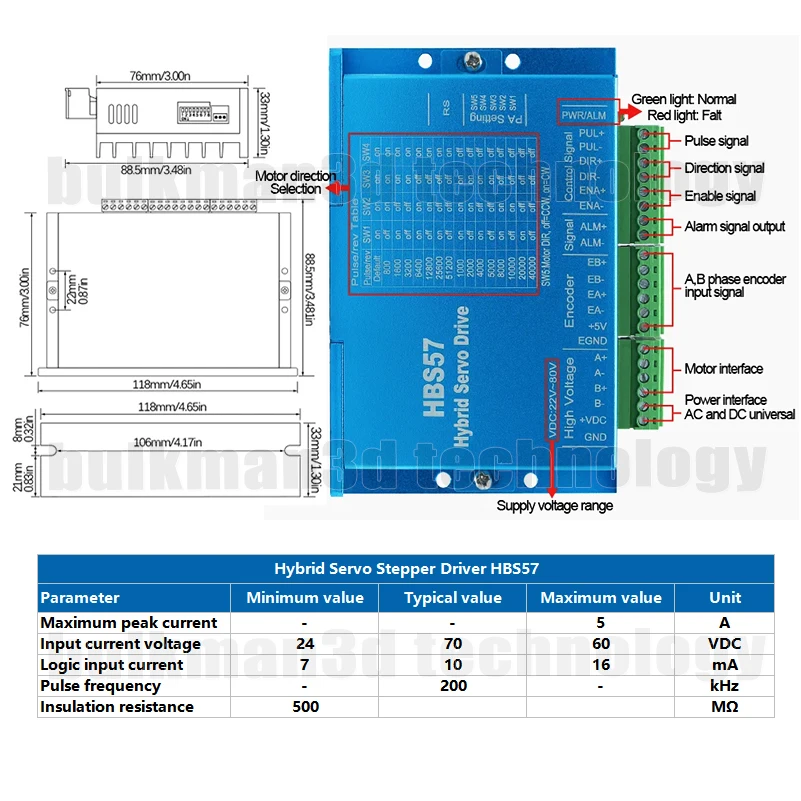

Features of HBS57 Stepper Drivers |

|

● Maximum peak current: 5A

● Impulse response frequency: 200KHz

● Subdivision: 200~51200ppr

● Voltage: DC16-70VDC

● Pulse Signal: 3.3V/5V/24V compatible. No string resistor required

● Protective function: overvoltage, overcurrent, tracking error out of tolerance

● Signal input Compatible:5-24V signal (Don’t need a resistor)

● Control Way: 32 bit DSP Vector Closed Loop

● Advantage: Closed-loop vector control to ensure high-speed and high-torque output of the motor and no step to lose.

|

|

Features of 2.2KW Water-Cooled Spindle Motor Kit |

|

● Net weight(2.2KW Water-Cooled): 5.5kg ● Specs(2.2KW Water-Cooled): ∅80 x 238mm ● Material: The cover is made of 304 stainless steel, and the water jack is high compression casting aluminium tube, red copper coil ● High Speed-7 series 4 Bearings: 7005 bearings (3pcs)+7002 bearing (1pc) ● Coaxality: 0.025 mm (2.5 microns) ● Voltage: 220~250 V or 110 V ● AC Rated Current: 8 A ● Frequency: 0-400 Hz ● Max Rotation Speed: 24000 R/min ● Water Cooled Run out: 0.01 mm ● Collet Type for 2.2KW: ER20 (28pcs sizes vary from 1mm/1.5mm/2mm/ 2.5mm/3mm/3.175mm/3.5mm/4mm/4.5mm/5mm/5.5mm/6mm/6.35mm/6.5mm/ 7mm/7.5mm/8mm/8.5mm/9mm/9.5mm/10mm/10.5mm/11mm/11.5mm/12mm/ 12.5mm/12.7mm/13mm) ● Power interface: GX16 water proof aviation plug marked with numbers 1, 2, 3, 4 (Numbers 1, 2 and 3 are connected to the inverter power U, V, W respectively. Number 4 is connected to the Earth wire) ● Lubrication: High temperature resistance grease lubrication. |

|

Features of 2.2KW Air-Cooled Spindle Motor Kit |

|

● Net weight(2.2KW Air-Cooled): 4.5kg ● Specs(2.2KW Air-Cooled): ∅80 x 195mm ● Material: The cover is made of 304 stainless steel, and the water jack is high compression casting aluminium tube, red copper coil ● High Speed-7 series 4 Bearings: 7005 bearings (3pcs)+7002 bearing (1pc) ● Voltage: 220~250 V or 110 V ● AC Rated Current: 8 A ● Frequency: 0-400 Hz ● Max Rotation Speed: 24000 R/min ● Run out: Less than 0.005mm ● Collet Type for 2.2KW: ER20 (28pcs sizes vary from 1mm/1.5mm/2mm/ 2.5mm/3mm/3.175mm/3.5mm/4mm/4.5mm/5mm/5.5mm/6mm/6.35mm/6.5mm/ 7mm/7.5mm/8mm/8.5mm/9mm/9.5mm/10mm/10.5mm/11mm/11.5mm/12mm/ 12.5mm/12.7mm/13mm) ● Power interface: GX16 water proof aviation plug marked with numbers 1, 2, 3, 4 (Numbers 1, 2 and 3 are connected to the inverter power U, V, W respectively. Number 4 is connected to the Earth wire) ● Lubrication: High temperature resistance grease lubrication. |

|