WorkUltra CNC Machine Full Kit - XPRO V5 GRBL |

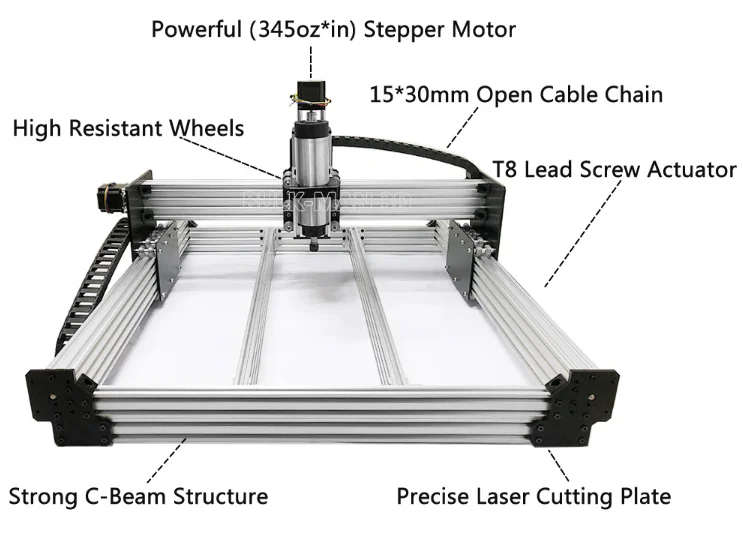

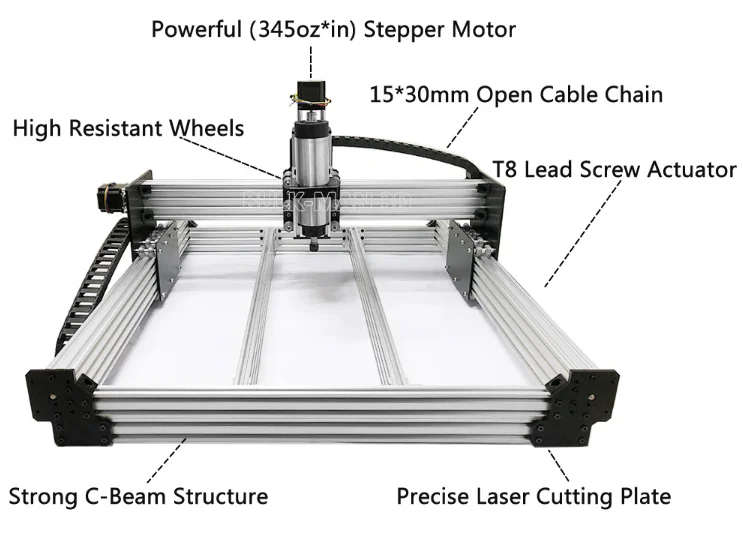

The WorkUltra CNC design has gone through different changes. WorkUltra Version 1 originally had the leadscrews placed in compression. All Bulk Man 3D’s WorkUltra kits now sold are Newest Version, with the major differences being the use of Tingle Tension System and longer leadscrews in the X and Y Axis. This helps to solve the problem of Whipping when for long length or faster Speed,which is very popular in CNC machine market.

Based on C-Beam, V-Slot, Xtreme Solid V-Wheels and TR8x8(P2) Leadscrews it is reliable. It has been carefully designed and can accurately cut foams, woods, plastics and aluminum to 0.1-0.2 mm accuracy or better.

The WorkUltra CNC Machine is a 4 axis (3 + 1) machine, this means there are 3 physical axis (X,Y,Z) and a slave axis of Y which is called the A Axis. The WorkUltra CNC Machine uses specific lengths of Extrusions and Leadscrews.

Advantage: This kit is the latest version comes with a new Tension System to minimise Lead Screw ‘Whip’ !

The WorkUltra CNC Full Kit is a self-assembly kit and comes with everything needed for building your CNC Machine. Other parts that are needed for you to perform your ‘first cut’ are: Baseboard, Power cord and Software.

This Full Kit Includes: |

|

● WorkUltra CNC Mechanical Kit - Screw Driven

● 2.45N.m Nema23 Stepper Motors

● Cable Drag Chain System

● Wiring Shielded Cable Kit

● + Options (Spindle Bundle Kit with Dust Cover 80mm/65mm)

2.2KW 110V/220V Water-Cooled Spindle Kit

1.5KW 110V/220V Water-Cooled Spindle Kit

1.5KW 110V/220V Air-Cooled Spindle Kit

● XPRO V5 Controller Kit

● XYZ Touch Probe

● Free Drill Bits (10pcs/set)

Attention:

● If you need belt driven WorkUltra CNC, please leave a message to us!

● The recommended maximum speed of a 1500mm lead screw is 400RPM, however, in practical terms no cut will be performed at this speed. Cuts and engraving are done at much slower speeds.

|

|

CNC xPRO V5 GRBL Controller |

The xPRO V5(We Recommend) is the most advanced GRBL CNC Controller in the world. Developed by Spark Concepts in USA who have been making GRBL CNC products for many years. It runs off a 32bit processor with over 4x the processing power of most other GRBL controllers. The xPRO V5 is pre-assembled and pre-flashed with the latest GRBL version. We recommend the xPRO V5 as the best controller option available. The stepper drivers are easily suitable for our High Torque Stepper Motors and can even power stronger motors such as Nema34.

Features:

● 32bit processor

● High powered Trinamic 6A Stepper Drivers

● Supports VFD control

● Easy Plug and Play

● SD Card which allows for offline use

● Both Wi-Fi connection & USB connection (user choice)

● This option is the best choice for both a novice starting out, and with people with experience and technical knowledge. |

|

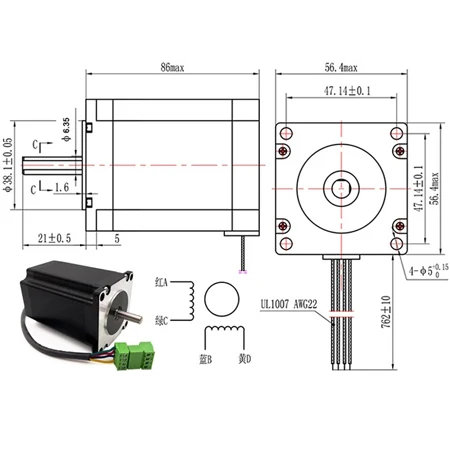

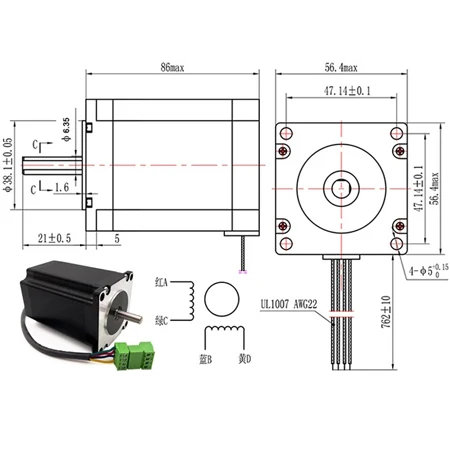

Nema 23 Stepper Motor – High Torque |

|

● Holding torque: 2.45N.m

● Rated voltage: 3.6V

● Rated current: 3A

● Step angle: 1.8°±5%

● Phase number: 2

● Insulation resistane: 100MΩ min.(500V DC)

● Insulation class: Class B

● Rotor inertia: 600g.cm2

● Resistance per phase: 1.2Ω±10%

● Inductance per phase: 4mH±20%

● Detent torque: 90mN.m

● Suit for Controller: CNC xPROV5, UC300, High Current GRBL etc.

Features:

- High Torque: Ideal for heavy-duty applications.

- Standard Size: NEMA 23 (2.3"x2.3") for easy integration.

- Precise Movement: 1.8° step angle for accuracy.

- Durable: Long-lasting and reliable.

- Versatile: Suitable for CNC, robotics, and automation.

- Efficient & Quiet: Low noise with high efficiency.

- Flexible Specs: Available in various current/voltage options.

|

|

2.2kW/1.5kW Water or Air Cooled Spindle Kit |

|

● Spindle Net weight: 5.3kg(2.2kW Water-Cooled), 4.2kg(1.5kW Water-Cooled), 2.6kg(1.5kW Air-Cooled)

● Spec: ∅80x 238mm (2.2kW Water-Cooled), ∅80x 208mm (1.5kW Water-Cooled), ∅65x 188mm (1.5kW Air-Cooled)

● High Speed-7 series 4 Bearings

● Power: 2.2kW

● Voltage: 220 ~250 V or 110V

● Frequency: 400 Hz

● Speed: 0-24000 R/min

● Air or Water Cooling

● Run-out off: less than 0.005 mm

● Grease Lubrication

● VFD Inverter 2.2kW 220V or 110V

● ER20 Collet: 2.2kW Water-Cooled (28pcs, size from 1mm/1.5mm/2mm/2.5mm/3mm/3.175mm/3.5mm/4mm/4.5mm/5mm/5.5mm/6mm/6.35mm/6.5mm/7mm/7.5mm/8mm/8.5mm/9mm/9.5mm/10mm/10.5mm/11mm/11.5mm/12mm/ 12.5mm/12.7mm/13mm)

● ER11 Collet: 1.5kW Water/Air-Cooled (15pcs, size from 1mm/1.5mm/2mm/2.5mm/3mm/3.175mm/3.5mm/4mm/4.5mm/5mm/5.5mm/6mm/6.35mm/6.5mm/7mm)

Key Difference:

● Water-Cooled: Better for heavy-duty, continuous tasks with quieter and cooler operation.

● Air-Cooled: Simpler, low-maintenance choice for moderate tasks with easier setup.

Our Suggestion:

● It depends on the application you are using them for.

● If you are milling timber then air cooled will be sufficient.

● If you are milling metals, or are using the spindle for more than 8 hours at one time then water cooled will be recommended.

|

|

Free Gift - 10PCS Drill Bits (Optional) |

The WorkUltra is a culmination of all our experience, feedback, and suggestions from selling the OX CNC Machine.

Based on C-Beam, V-Slot, Xtreme Solid V-Wheels and Tr8*8(P2) Lead Screws it is strong, accurate and reliable.

Compatible Material for Cutting/Milling/Engraving: Aluminium / Hard Wood / Soft Wood / Oak / Plexi Glass / Delrin / HDPE / Foam.

Workable Dimensions(mm): |

Frame Size |

Working Area |

500x750mm |

300x520mm |

750x750mm |

550X520mm |

750x1000mm |

550x770mm |

1000x1000mm |

800x770mm |

750x1500mm |

550x1270mm |

1000x1500mm |

800x1270mm |

1500x1500mm |

1300x1270mm |

Please Note:

MDF Working Table is NOT included with this kit.

We do not provide technical support for software debugging.

GRBL Software is not included with this kit. It can be free download directly from the official website.

Any Mains power connections must be installed by a Licensed electrician or suitability qualified person.

|

Z Travel Explained

The WorkUltra has two spoilerboard support configurations. One with a travel of 66mm, and a lower one with a travel of 106mm. The reason for the two configurations is that if the machine is always used to cut thin materials, for accuracy reasons it is better to have the work piece as close to the Z-Actuator as possible, so in this case the machine should be setup in the higher 66mm travel configuration.The higher configuration has a Z travel of 66mm, with a 12mm spoiler board, this will reduce the Z travel to 54mm. In this case 54mm is maximum thickness of material that will fit on the machine.To calculate the max cutting depth for a chosen piece of material it is:

● Max Cutting Depth = Z travel – Material Thickness

For instance a setup with a 12mm spoiler board, the max Z travel is 54mm, so when cutting into a material 30mm thick the max cutting depth would be:Max Cutting Depth = 54 – 30 = 24mmThis means with a 30mm piece of material it would not be possible to cut it the whole way through.The max thickness that can be cut the whole way through is half the Z travel. So with a Z travel of 55mm, 27mm is the maximum thickness of material that could be cut the whole way through. And for the lower configuration the maximum thickness that can be cut the whole way through is 47mm.

Z Height

54mm Or 94mm Travel, 27mm Or 47mm Workable depth, with a 12mm spoilerboard. The spoilerboard supports have two height configurations, these are the maximums for each configuration.

Motion

Drive System- ACME Lead Screws Or GT3 Timing Belts

Linear Guides- Polycarbonate wheels on anodized C-Beam/V-Slot Extrusion.

Motors- NEMA23 (175oz*in or 345oz*in) Stepper Motors (X, Y & Z)

Accuracy- 0.05 – 0.10mm (Screw Driven) Or 0.10 – 0.20mm (Belt Driven)

Note

Maximum recommended speed for Lead Screws 1000mm or greater is 400RPM.

Credit

” V-Slot ” and ” C-Beam ” are registered trademarks of OpenBuilds LLC as released under the Creative Commons Licence “Attribution-ShareAlike”

|

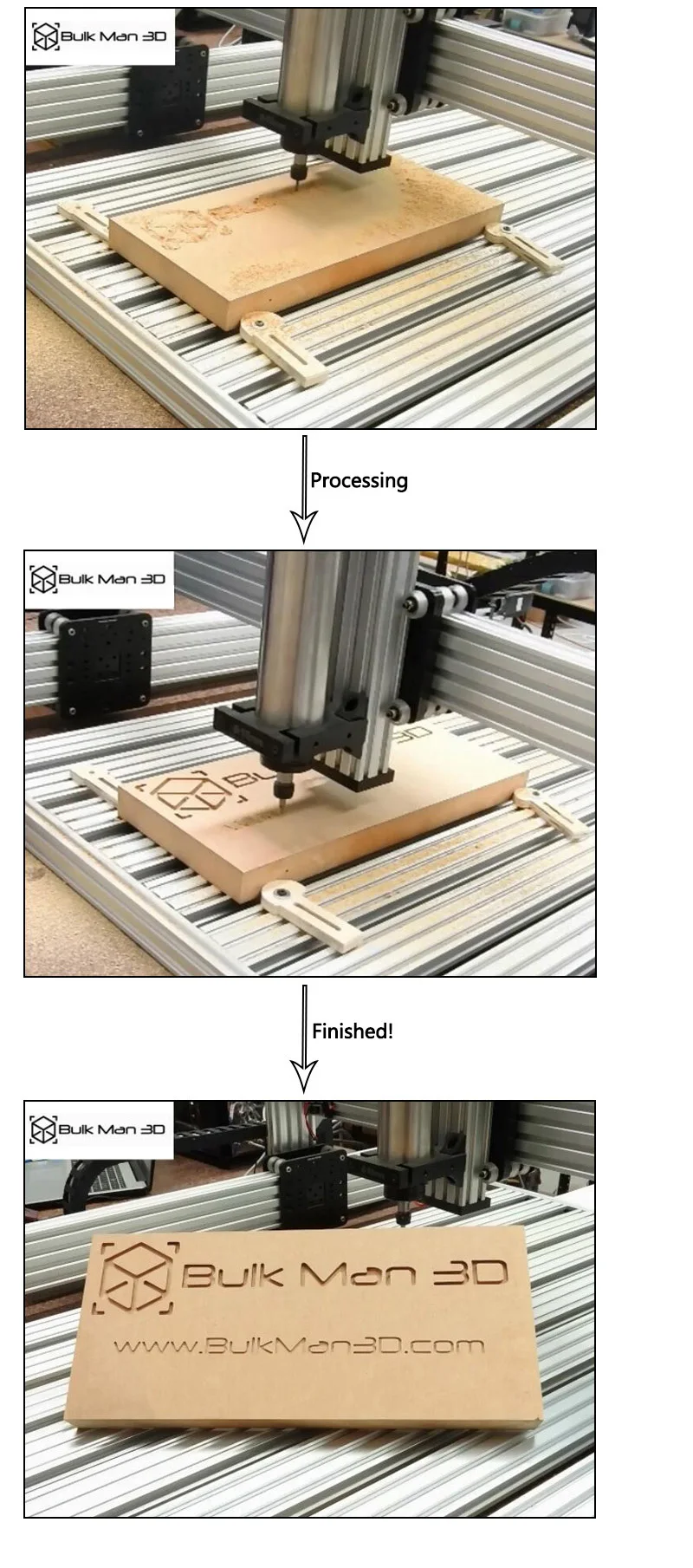

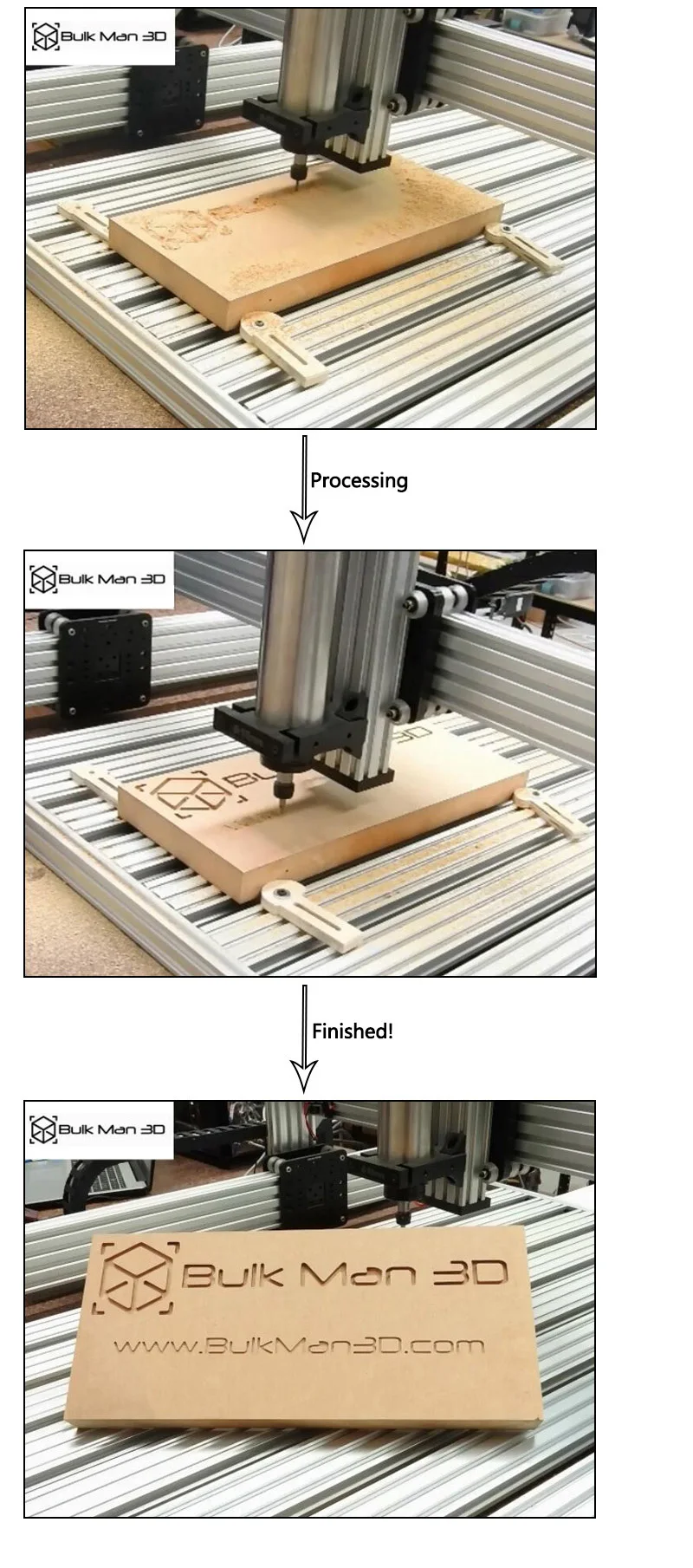

Look! How the WorkUltra CNC is Cutting our Bulk Man 3D Logo!