SPECIFICATIONS

Applicable label width: 0~150mm(can be customized)

Brand Name: NoEnName_Null

Control mode: man-machine interface

Dimension: 900*600*1500mm

Material: stainless steel + aluminum alloy

Model: LY-670

Model Number: LY-670

Motor: stepping motor

Origin: Mainland China

Power: 300W

Production speed: 40m/min

Voltage: AC220V

Weight: 150

is_customized: No

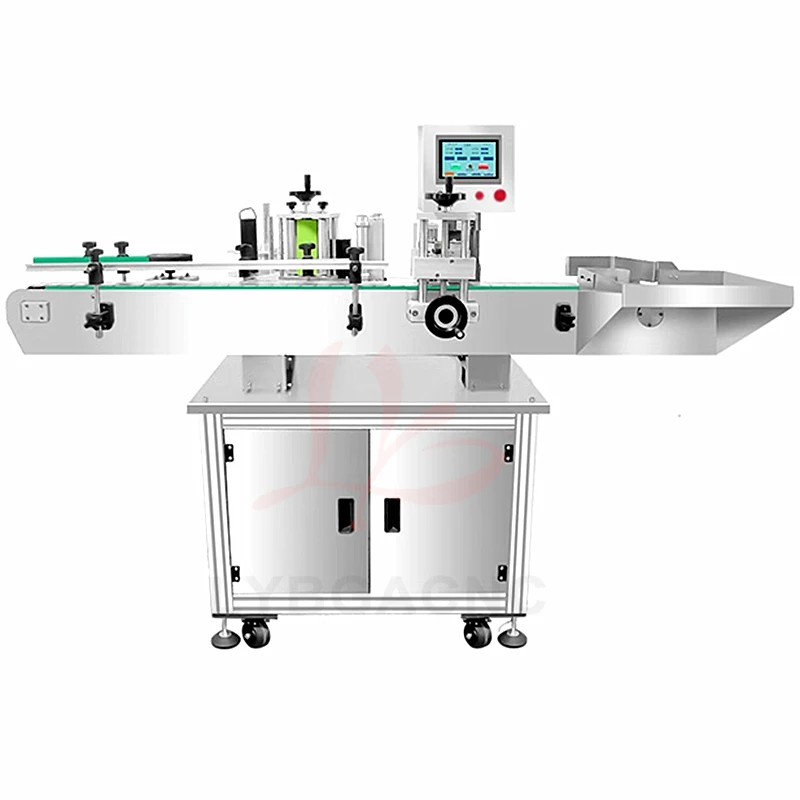

Large Round Bottle Labeling Machine LY-670 Automatic Assembly Line Labeling Sticker Device for Food Packaging Bags Carton Boxes Labeler With Conveyor Belt

输送台尺寸:

|

Standard conveyor table size |

|

|

Conveyor Belt Length |

150cm |

|

Conveyor belt width |

19cm |

|

Height of machine surface from the ground |

72cm |

|

Total width of conveyor belt |

25cm |

|

Total load |

15kg |

机器参数:

|

Machine Parameters |

|

|

Model |

LY-660 |

|

Voltage |

AC220V |

|

Power |

300W |

|

Production speed |

40m/min |

|

stainless steel + aluminum alloy |

|

|

Motor |

stepping motor |

|

Control mode |

man-machine interface |

|

Applicable label width |

0~150mm(can be customized) |

|

Dimension |

900*600*1500mm |

|

Weight |

45kg |

Detailed image text information

Advantage

High labeling precision: accurate positioning

Intelligent identification: intelligent labeling

Automatic counting: automatic counting

Adjustable labeling structure: up and down,left and right movement

Intelligent frequency converter: ensure smooth labeling

Adjustable speed: can be adjusted according to the demand

Intelligent touch screen: easy to operate

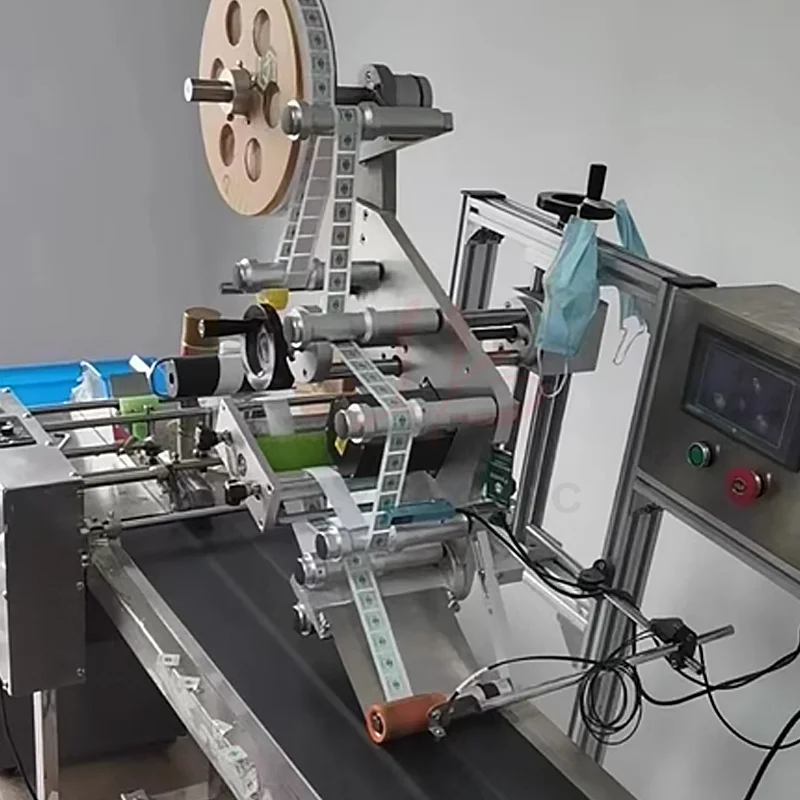

Dual-stage separator: more stable label tensioning force

Wide range of applications

This plane labeling machine is suitable for a variety of square, flat objects on the surface of the labeling or labeling anti-counterfeiting labels; widely used in cosmetics, food, beverage,pharmaceutical and other industries

Optional assembly line table

Match with conveyor table, separator and other assembly lines to complete the product labeling in-line

Product Details

1.Stepping motor Adopting high-precision stepping motor for stable operation

2.Label detection Recognize the product and label it

3.Labeling device Prevent labeling blistering after the second labeling to make the labeling more flat.

4.Adjustment mechanism Can be moved up, down, left and right to accommodate a variety of labels

5.High-definition touch screen Operation is more convenient and simple with one screen in hand.

6.Adjustable foot Adjustable screws, adjust the foot of the equipment, so that the machine to maintain stable

Precision labeling head

Ensure that the label conveying normal work, to prevent label breakage label peeling according to their own labels,adjust the head height, front and rear position, can be adapted to a variety of labels.

Electronic Tag Detection

No label, no product, no labeling. to ensure the normal operation of the machine labeling

High-definition touch screen

Simple operation, one screen in hand, operation all have