SPECIFICATIONS

Brand Name: NoEnName_Null

Certification: CE

Cooling Method: Water-cooling

Fiber Length: 10m

High-concerned chemical: None

Is Smart Device: Yes

Laser Power: 1500/2000/3000w

Laser Wavelength: 1080±5nm

Model Number: HFW1500

Origin: Mainland China

Rated Voltage: 220V

Use: Welding metal

Voltage: 220/380V, 50/60Hz

Wavelength: 1080nm

Working Temperature: 10-40℃

Jinan HonorFuture CNC Machiney Co.,Ltd:

Email: sales08@honorfuturecnc.com

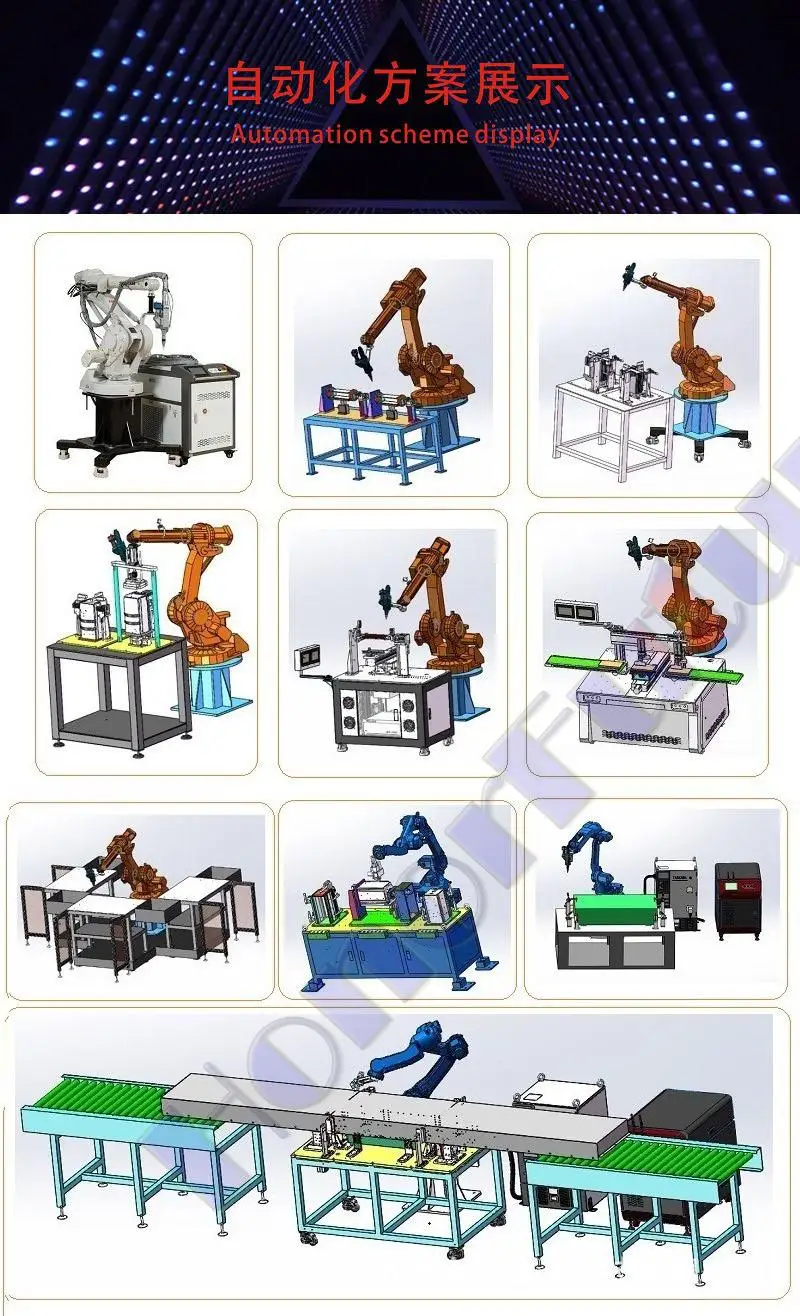

Automatic Robot Arm Welding Machine Six AIXS Robotic Arm Welder Fiber Laser

Welding Machine

Machine Benefits

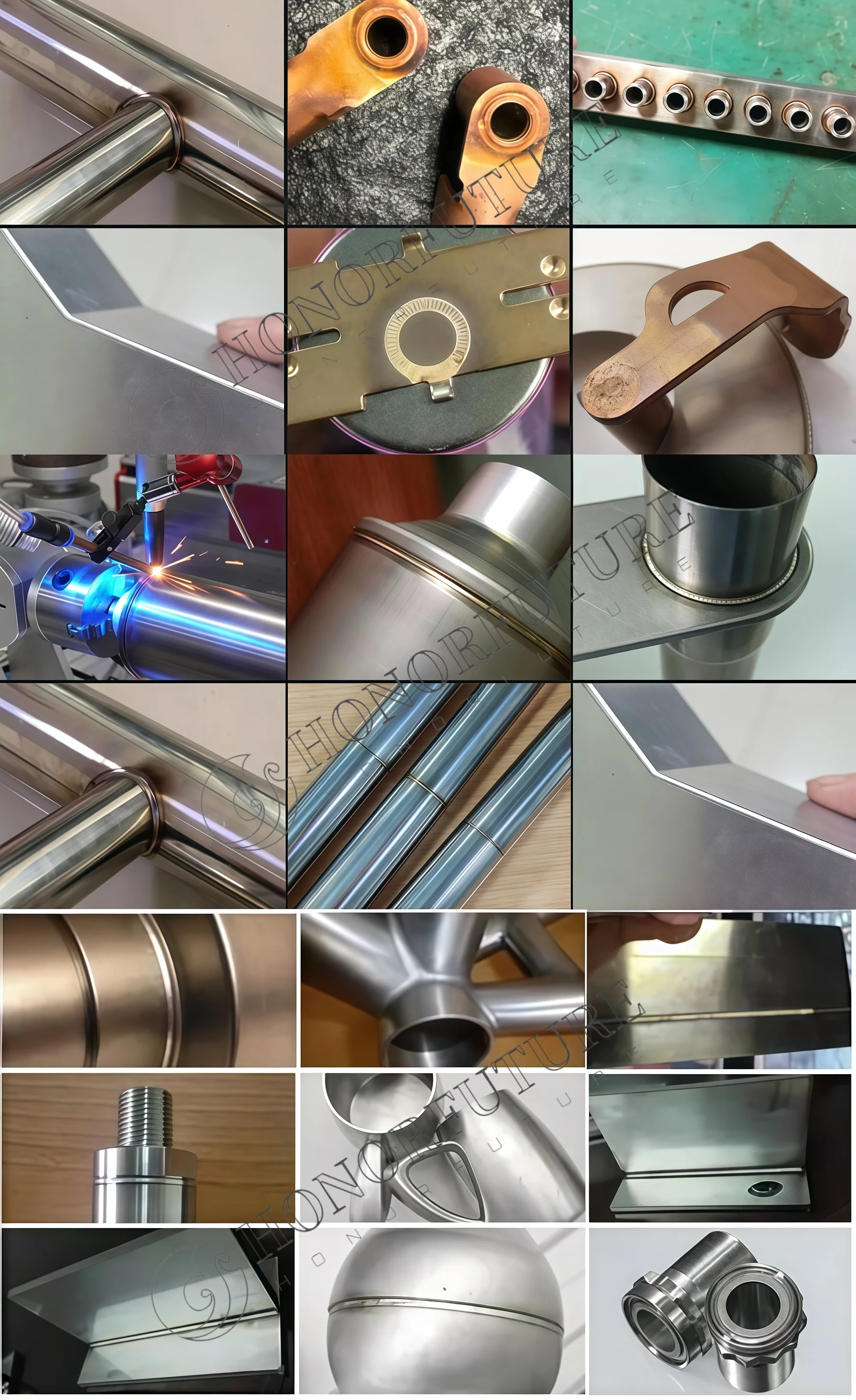

Exceptional welding quality and consistency

Robots operate tirelessly, precisely replicating human welding trajectories and parameters. This eliminates the influence of human emotion, fatigue, and skill variations, ensuring every product's weld seam is perfectly consistent.

Significantly enhanced production efficiency

24-hour continuous operation: Effortlessly supports three-shift uninterrupted production, substantially boosting output capacity.

Faster welding speeds: Robotic movement speeds far exceed those of skilled welders, with rapid idle travel between tasks.

Reduced torch/tool changeover time: High-end systems integrate automatic tool changers for swift switching between different welding torches or grippers.

Lower long-term costs

Reduced labour costs: A single robot can replace multiple senior welders.

Minimised material wastage: Exceptional repeatability ensures minimal rework and scrap rates, conserving materials and labour hours.

Optimised consumable usage: Precise control of welding parameters reduces wire, gas, and electrical consumption.

Enhanced working environment and safety

Workers are freed from hazardous conditions involving toxic fumes, intense arc light, high temperatures, and repetitive strain injuries, transitioning to safer roles in programming, monitoring, and maintenance.

Exceptional Flexibility and Programmability

Adaptation to new product variants achieved through simple programme modification, making it ideal for flexible production (small batches, diverse product lines). When integrated with 3D vision systems, it enables automatic weld seam location and tracking.

Machine Applications

Automotive Manufacturing

The largest user. Employed for welding virtually all components including body panels, chassis, frames, exhaust pipes, and seats. Hundreds of robots on automotive production lines have become emblematic of modern industry.

Construction Machinery

Welding large structural components such as booms, dipper arms, and frames for excavators, cranes, and loaders.

Rail Transport

Welding carriages, bogies, and other components for high-speed trains and metros.

Home Appliances

Washing machine drums, refrigerator frames, air conditioner compressors, etc.

Hardware & Furniture

Metal tables and chairs, shelving units, security doors, etc.

Aerospace & Shipbuilding

Welding aircraft components and ship hull modules in fields demanding the highest quality standards.

Company Infromation

Jinan HonorFuture Machinery CO.,LTD has been committed to the research, development, production and sales of Fiber Laser Cutting Machine, Laser Welding Machine, Laser Cleaning Machine, CNC Router, Co2 Laser Machine, CNC Plasma Cutter, Other products etc. for years.

We can provide high quality, multifunctional CNC machines for customers domestic and abroad. After several years of rapid development since 2012, we have diversified products that can provide optimal CNC solutions for our customers.

Why Choose HonorFuture?

Please just contact me for more information

Email: sales08@honorfuturecnc.com